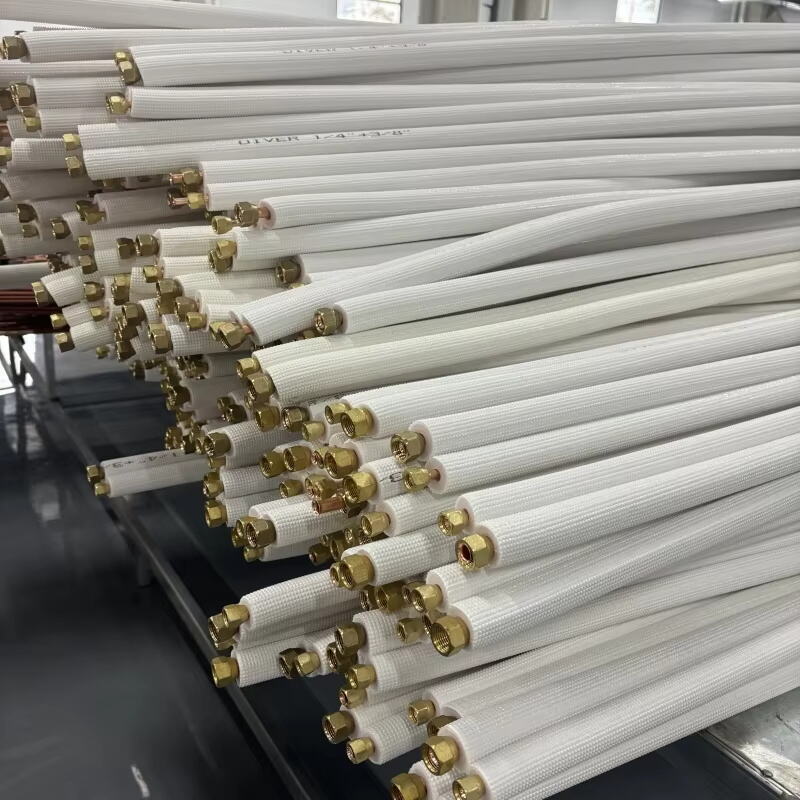

What Are Copper Pair Coils?

Copper pair coils are basically made from pure copper because nobody else does better when it comes to conducting electricity or heat. Most of these coil setups have two separate tubes wound together - one carries the refrigerant while the other brings it back after doing its job, which makes the whole heat transfer process work much better. The way they're built helps maintain good performance even when things get hot or cold in different parts of the system. These coils come in all sorts of sizes too. Some might be thin and long for tight spaces, others thicker for heavy duty applications. That flexibility means they fit right into everything from home air conditioning units to industrial refrigeration plants where precise temperature control matters most.

Historical Use in HVAC Systems

Copper has long stood out as the go to material for HVAC systems because it conducts heat so well, something engineers noticed way back when they first started building refrigeration units. The stuff just doesn't break down easily either, which is why manufacturers keep coming back to copper year after year despite all the new materials on the market. What makes copper really shine though is how those natural properties actually improve how whole systems work over time. We're seeing this play out right now as newer HVAC designs focus more on saving energy. Many companies are starting to incorporate copper pair coils into their equipment, which helps maintain consistent temperatures while using less power. The fact that copper keeps getting adopted in these cutting edge applications shows it hasn't lost its edge at all. Systems built with copper components tend to last longer too, making them a smart investment for anyone dealing with climate control challenges.

Role of Copper Pair Coils in HVAC Heat Transfer

Heat Exchange Mechanisms

Copper pair coils play a really important role when it comes to getting good heat exchange going inside those HVAC systems we rely on so much. Basically, they work through both conduction and convection processes, which helps them transfer heat efficiently while keeping indoor spaces at comfortable temperatures. When looking at coil design, one thing stands out: surface area matters a lot. Bigger surfaces just plain work better for moving heat around, which makes sense if anyone has ever touched something hot and felt how quickly it transfers warmth. This careful attention to design lets HVAC units keep rooms at stable temps without constant fluctuations. Copper remains king of materials because nobody else conducts heat quite like it does, which explains why most manufacturers stick with copper when trying to get their HVAC systems performing at peak levels.

Refrigeration Cycle Integration

Copper pair coils play an important part in refrigeration cycles because they help move heat away from refrigerants into the air around them. These coils show up in both evaporator units and condenser sections, making those parts work better together thermally speaking. Technicians need to know how copper pair coils fit into the whole system since this knowledge helps them tweak performance settings and keep equipment running longer before needing replacement. When copper conducts heat so well, it actually makes cooling faster while saving on electricity costs too something manufacturers care about more now than ever before. Copper gets chosen over other materials mainly because it lasts longer under normal operating conditions and transfers heat much better than alternatives like aluminum would.

Advantages of Copper Pair Coils Over Alternatives

Superior Thermal Conductivity

HVAC technicians tend to prefer copper pair coils because they conduct heat so much better than alternatives such as aluminum or plastic components. The superior conductivity means these coils transfer heat quicker, helping systems hit target temperatures faster and stay there longer. For building managers, this translates into real savings on electricity bills while keeping everyone comfortable inside. Research conducted over several years indicates copper coils boost efficiency by around 15-20% compared to other materials. Although initial installation costs might be higher, most facilities see a return on investment within just a couple of years through reduced power usage and fewer maintenance issues down the road.

Durability in Harsh Environments

Copper pair coils stand out because they last so long, especially when installed in tough spots like near the ocean where salt air eats away at metals. The way copper resists rust and breakdown keeps these coils intact even when temps swing wildly from freezing nights to scorching days. Most other materials just wouldn't hold up over time. When something lasts longer, that means technicians don't need to replace parts as often or fix problems down the road. Maintenance budgets shrink while system performance stays strong year after year. Real world tests back this up too many installers report seeing copper components still working well after decades in places where steel would be completely shot by now. For anyone looking to build HVAC systems that actually survive the test of time, copper remains the go to material despite all the newer alternatives on the market.

Maintenance and Longevity of Copper Coils

Best Practices for Cleaning

Copper coils need regular cleaning if they are going to perform at their best within an HVAC system. When technicians check them on schedule and clean away any buildup, it stops problems from developing that would slow down heat transfer over time. For cleaning jobs, gentle products work better than harsh chemicals, along with soft bristled brushes so the delicate copper doesn't get scratched up during the process. Sticking with this kind of routine care actually makes copper coils last longer while keeping the whole HVAC system running smoothly, which means fewer expensive repair calls down the road. The bottom line is simple maintenance protects those coils from damage and keeps energy bills from climbing unnecessarily month after month.

Signs of Wear and Replacement

Spotting when copper pair coils start showing their age matters a lot if we want to avoid big system failures down the road. What typically happens? The coils might change color, develop leaks, or just look physically damaged somehow. Catching these problems before they get bad means getting ahead of maintenance needs and giving the whole system a longer life span. Most technicians swear by maintaining detailed records of what condition the coils are in over time. This kind of tracking makes it much easier to notice small changes that could signal bigger trouble later on. Regular checks aren't just about avoiding expensive surprises either. They help keep HVAC systems running smoothly day after day, so when replacement does eventually come around, it's something planned for instead of an emergency situation.

Environmental Benefits of Copper in HVAC

Energy Efficiency Impact

The way copper conducts electricity so well actually makes systems run more efficiently, which helps cut down on those pesky greenhouse gases coming from HVAC equipment. When we talk about copper coil pairs specifically, they have these amazing heat transfer characteristics that keep cooling performance steady while using less power overall. Some research done by major energy groups suggests that switching to copper coils could save around 30 percent on energy bills in certain situations. Lower energy consumption means real money saved for people paying their utility bills, plus it does something good for the planet too since less fossil fuel needs burning to generate all that extra power. For anyone looking at long term solutions for greener buildings, incorporating copper based components into heating and cooling systems represents a pretty solid investment in sustainability goals.

Recyclability and Sustainability

What makes copper so special? Well, it can be recycled over and over again without losing quality at all, which is why many see it as a green option for heating and cooling systems. When we recycle copper instead of digging up fresh materials from mines, we save tons of natural resources that would otherwise get depleted. The whole life cycle stays pretty balanced too, helping keep our planet's ecosystems in check. There are already solid recycling initiatives out there specifically for the HVAC industry. These setups basically keep copper moving through different uses rather than ending up in landfills. That means less waste overall and better chances at hitting those sustainability targets companies talk about so much these days. For anyone working with or buying HVAC equipment, going with copper coil pairs isn't just smart business—it's also standing up for something bigger than profit margins.

Applications of Copper Pair Coils

Residential vs. Commercial Systems

Copper pair coils play important roles in residential and commercial HVAC systems, though their functions vary based on where they're installed. For homes, the focus tends to be on keeping things quiet and taking up minimal space since nobody wants loud machinery rattling around in their living room. That's why residential units often have smaller footprints and sound dampening features built right in. Commercial installations tell a different story altogether. These systems need to handle massive square footage efficiently without breaking down under constant demand. Think about office towers or manufacturing plants running 24/7. When technicians get familiar with how these coils perform in different contexts, it makes all the difference when selecting equipment for specific buildings. A coil that works great in a single family home might completely fail in an industrial setting if not properly matched to the application.

Innovations in HVAC Technology

The latest developments in HVAC tech have made these systems much better at saving energy and using materials more wisely, largely because of things like microchannel tech. The way coils are designed now transfers heat better while actually needing less material than before. Copper coils get special coatings and treatments these days too, which means they last longer and work better when it comes to energy consumption. This translates to fewer replacement costs down the road for building owners. A lot of companies in the industry are starting to experiment with mixed systems that combine traditional copper coils with solar power or other green energy options. What we're seeing is a real shift happening right now toward HVAC equipment that works well but doesn't hurt the planet either.

FAQs

What is the main purpose of copper pair coils in HVAC systems?

Copper pair coils are used in HVAC systems primarily for efficient heat exchange, leveraging copper's superior conductivity to transfer heat effectively and regulate temperatures within indoor environments.

How do copper pair coils improve energy efficiency?

By offering better thermal conductivity compared to other materials, copper pair coils facilitate faster heat exchange, which helps HVAC systems reach desired temperatures quickly, reducing energy consumption and lowering costs.

Why is copper preferred over other materials for coils?

Copper is preferred due to its excellent thermal and electrical conductivity, durability in harsh environments, and the ability to maintain structural integrity under extreme conditions.

What are the signs that copper coils need replacement?

Signs include discoloration, leaks, and physical deformation that may indicate the need for intervention or replacement to maintain system efficiency and prevent breakdowns.

Can copper pair coils be recycled?

Yes, copper coils are completely recyclable without quality compromise, contributing to sustainability and promoting a circular economy in HVAC manufacturing.