Why 50ft is the Optimal Length for AC Line Sets

Balancing Coverage and Practicality in Residential Systems

Getting the right line length for an air conditioning system makes all the difference when it comes to how well it works and covers space in homes. The 50 foot line set offers quite a bit of flexibility across different installation situations. Homeowners don't have to tear things apart just to get the unit where it needs to go. What's really nice about this setup is that it helps distribute cool air evenly around rooms without wasting power. Research from ASHRAE shows that something as simple as picking the correct line length, say around 50 feet, actually has a big impact on both energy savings and system performance. When someone goes with this standard length, they're looking at better system operation without having to compromise on comfort levels or spend extra money down the road.

Attic-to-Ground and Split-Level Installation Scenarios

When looking at different ways to install HVAC systems, the 50 foot line set works really well in those split level houses where there's a big difference between floors. For installations going from attics down to ground level, having that extra length means fewer sharp turns in the lines, which keeps things running smoothly and maintains good airflow throughout the house. Most contractors see that the typical height differences in homes match up pretty closely with what a 50 footer can handle, so it becomes a go to option for lots of residential projects. The length fits nicely into most existing building structures without causing headaches during installation, and makes air conditioners work better no matter how strange the layout might be. From my own experience shopping around for AC solutions, understanding just how versatile these 50 foot sets are makes choosing equipment much easier, and cuts down on the frustration that comes with complicated installations.

## Key Benefits of Pre-Flared 50ft Air Conditioning Line Sets

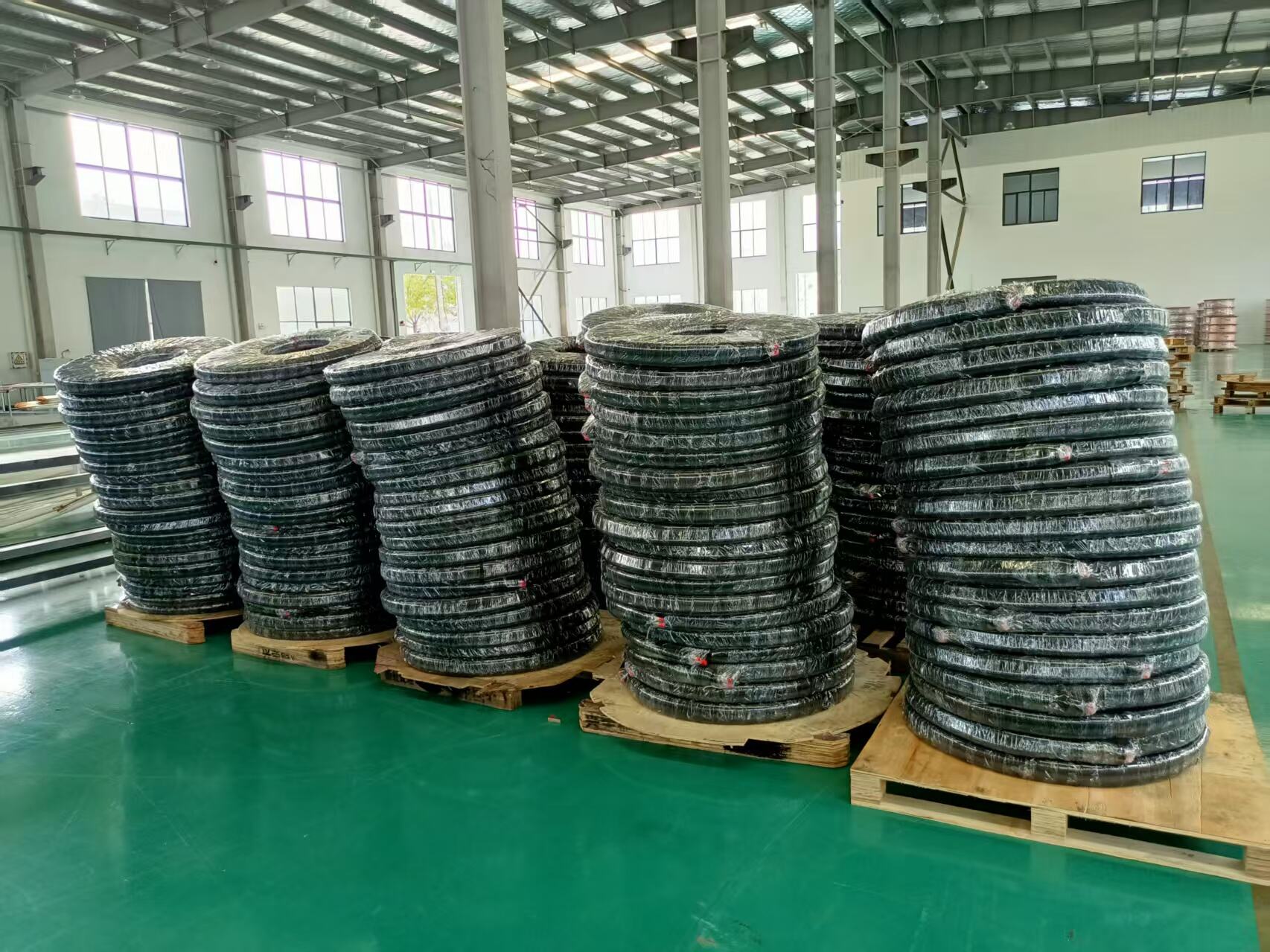

Eliminating Field Brazing with Factory-Sealed Copper Tubing

Copper tubing that comes factory sealed makes installation much easier since there's no need to do all that tedious field brazing work. Installers save both time and headaches when putting together air conditioning systems this way. Fewer chances for mistakes means fewer leaks down the road, which keeps the whole system running longer without problems. According to what many in the industry have seen, most refrigerant losses actually come from those field brazing errors. That's why more professionals are turning to these pre-sealed options these days.

Continuous Insulation for Reduced Thermal Loss and Moisture

Keeping those 50 foot line sets properly insulated makes all the difference when it comes to holding refrigerant temperatures steady and cutting down on heat loss, which ultimately means better system performance overall. Without proper insulation, these lines tend to soak up moisture from the surrounding environment. That moisture buildup not only forces the AC unit to work harder (and cost more money) but can actually cause physical damage over time. According to HVAC industry reports, well insulated systems typically see around 15-20% improvements in energy efficiency metrics. For homeowners or facility managers wanting to get the most out of their cooling equipment while keeping maintenance costs low, investing in quality insulation materials really pays off in both short term savings and long term reliability.

Minimized Joints = Lower Refrigerant Leak Risks

Fewer joints in an air conditioning line set means there's less chance of refrigerant leaking out, which keeps the whole system working properly. Studies have found that when there are fewer connection points, the system just doesn't leak as much over time. That's why many technicians recommend going with those longer 50 foot line sets whenever possible. And let's not forget about what this means for the environment either. Less refrigerant escaping into the atmosphere helps reduce our carbon footprint significantly. Homeowners should know this stuff matters because fixing leaks later costs money and causes unnecessary damage to both equipment and planet alike.

Labor & Cost Efficiency in Modern HVAC Installations

Pre-Dehydrated Lines Accelerate Vacuum Process

Air conditioning line sets that come pre-dehydrated make installation much easier since they cut out all that time-consuming vacuuming work, so they tend to save money in the long run. When HVAC technicians go with these pre-treated lines instead of traditional ones, they spend way less time on labor, meaning installations get done quicker without sacrificing quality standards. Most seasoned pros in the field will tell anyone who asks how much time these lines actually save during installs, and those minutes add up fast when multiplied across multiple jobs. Real world stats from countless HVAC setups show pretty impressive reductions in installation time and better overall efficiency with these modern line options. The bottom line is simple math really – faster installations mean getting projects wrapped up earlier and sending invoices to clients sooner than would otherwise be possible.

Standardized Lengths Simplify Contractor Inventory Management

Standardized 50 foot line sets give contractors a real edge when it comes to buying materials and keeping track of stock. When companies deal with all sorts of different line lengths, they end up spending extra time figuring out what they need next month or next quarter. This creates problems with getting products on time and usually means paying more for storage space than necessary. Going with the standard 50 foot size cuts down on these headaches because there's just one item to order and keep in stock. Most experienced professionals will tell anyone who asks that sticking with standard measurements makes life much simpler in the long run. The HVAC industry has seen this work wonders for years now, helping businesses maintain steady operations without constantly worrying about last minute shortages or overstock situations.

Reduced Field Measurements for Faster Deployment

Standardized 50 foot line sets cut down on all those tedious field measurements technicians usually have to make, which speeds things up quite a bit for HVAC pros in the field. The time saved translates into real money savings when it comes to labor costs something every contractor is watching these days. When installations go faster because there's no back and forth measuring, everyone benefits including the bottom line. Most seasoned HVAC folks will tell anyone who asks that cutting down on measurement headaches and getting systems installed quicker makes a world of difference in project outcomes. Sure, there are exceptions where custom setups still require some on site adjustments, but overall ditching the constant measuring just makes the whole installation process run smoother while keeping costs under control.

## 50ft vs. Shorter Line Sets: When Size Matters

Avoiding Risky Couplings in Long Horizontal Runs

Short line sets often come with coupling problems, particularly when running horizontally over long distances where failures tend to happen more frequently. The numbers back this up too many installations show increased breakdowns in longer horizontal runs with several couplings strung together, and this definitely affects how well the whole system works. Going with a 50 foot line set cuts down on the number of couplings needed, so there are fewer spots where things might go wrong. Most technicians will tell anyone who asks that fewer couplings mean better longevity for these AC line sets. Installing with longer line sets makes life easier for everyone involved, creates a stronger installation overall, and honestly gives installers a lot less to worry about down the road.

Maintaining Proper Refrigerant Flow in Extended Systems

Using a 50 foot line set helps maintain good refrigerant flow in those longer air conditioning setups, which makes them work better than shorter ones. Studies have shown there's definitely a connection between how long the line is and how well refrigerant moves through it. Longer lines just let things flow more smoothly overall. When everything stays within the right range, the whole system runs more efficiently. That's why many technicians actually recommend going with the 50 foot option when possible. It keeps things running consistently without surprises, something that matters a lot in real world installations where conditions can vary quite a bit from one job site to another.

Code Compliance for Maximum Linear Footage Between Units

Getting HVAC systems up to code isn't just good practice it's absolutely necessary for proper installation work. Most local building codes allow for around 50 feet of line set length between indoor and outdoor units before running into issues. Following these regulations does more than keep things safe it actually makes life easier during inspections and keeps warranties valid when problems arise later on. The National Electrical Code specifically addresses this stuff, so ignoring those rules could lead to all sorts of headaches down the road. When contractors go with standard 50 foot line sets, they save time on site because everything fits within permitted limits right out of the box. Plus, sticking with approved lengths means fewer callbacks from inspectors and better long term performance from the whole system.

## Industry Standards Supporting 50ft Line Set Adoption

ASHRAE Guidelines for Copper Tubing Lengths

ASHRAE's recommendations play a big role in getting HVAC technicians to use those 50 foot copper lines in their systems. The guidelines point out that going with longer runs like 50 feet actually makes the whole system work better, especially when it comes to saving energy over time. According to ASHRAE, sticking with these recommended lengths is pretty much standard practice if someone wants to cut down on wasted energy and get maximum cooling power from their equipment. When HVAC pros follow these specs, they're basically setting up air conditioners to run at their best, which means less breakdowns and more consistent performance across different seasons. The fact that ASHRAE backs this approach gives contractors confidence that using these longer lines isn't just good for business but also meets industry expectations for quality installations.

Energy Star Recommendations for Insulated Line Sets

The Energy Star program promotes insulated line sets, especially those around 50 feet long, as a way to cut down on energy use while making AC systems more sustainable. Insulated lines of this length actually save quite a bit of power, which means less electricity gets wasted during operation. This makes sense when looking at real world installations where heat loss through uninsulated copper pipes has been measured at up to 30% in some cases. The benefits go beyond just saving money on utility bills too. When contractors install these properly insulated runs between indoor and outdoor units, they're helping building owners meet increasingly strict green building codes. Plus, over time, these small improvements across many systems add up significantly to national energy conservation efforts.

Warranty Protection Through Approved Configurations

Most manufacturers include warranty protection details in their recommended setup instructions, especially regarding things like 50 foot line sets for HVAC systems. Studies have shown that when installers follow these standard practices, they tend to see far fewer warranty claims down the road. Take it from field technicians who've seen firsthand how installations matching manufacturer specs just work better overall. Strict adherence to these configuration requirements not only makes claiming warranties easier but also protects against unexpected breakdowns later on. Following manufacturer guidelines isn't just about paperwork either it actually makes a real difference in how long an air conditioning system will last before needing major repairs or replacement parts.

## Addressing Common 50ft Line Set Concerns

Managing Excess Tubing in Compact Installations

Too much tubing packed into tight spaces creates real headaches for installers. The problem isn't just looks either. Those extra feet hanging around take up precious room and complicate the whole setup process. We've all seen what happens when someone tries to cram too long a line set into an already crowded panel box. Strategic planning becomes essential here. Make sure the tubes don't cross paths with other components or block access points. Sometimes going vertical rather than horizontal saves tons of space. Many technicians swear by flexible mounting brackets that let them wrap up loose ends neatly against walls or equipment frames. These little tricks make all the difference between a clean install and something that looks like a spaghetti factory exploded.

Preventing Oil Trapping in Extended Suction Lines

Long suction lines create problems with oil getting trapped inside them, which really affects how well the whole system works. When oil gets stuck in these traps, it leads to more wear on components and makes the AC run worse than it should. That's why getting the installation right matters so much for technicians working on these systems. Most pros suggest putting traps at regular spots along the line and making sure there's enough slope so the oil flows back to where it belongs in the compressor. These simple steps stop oil from collecting in unwanted places and keep everything running smoothly as intended. The numbers don't lie either - some studies have found that bad line length choices can cut efficiency down by around 20% in certain cases. Following proper installation guidelines from experienced technicians helps maintain good performance over time while extending the life of expensive equipment.

UV-Resistant Jacketing for Outdoor Section Protection

When 50 foot line sets are left outside, UV resistant jacketing becomes really important for keeping them from breaking down over time. Sunlight actually breaks down the plastic tubing pretty badly, which means the whole AC system doesn't work as well and won't last nearly as long. Most companies selling these line sets will talk up how good UV resistant materials are because they do make a real difference in how long the equipment lasts before needing replacement. We're talking about stuff like top quality plastics and metals that have been specially coated to handle whatever Mother Nature throws at them - think sun exposure, rainwater soaking in, and all those hot cold cycles throughout the seasons. Getting this protection right means technicians don't have to keep replacing failed lines every few years, saving both money and hassle down the road.

FAQ Section

What is the optimal length for an air conditioning line set?

The optimal length for an air conditioning line set is typically 50ft. This length balances coverage and practicality, ensuring efficient cooling and energy use.

Why are fewer joints in a line set beneficial?

Fewer joints in a line set reduce the risk of refrigerant leaks, maintaining the integrity and performance of the air conditioning system over time.

What are the benefits of using factory-sealed copper tubing?

Factory-sealed copper tubing eliminates the need for labor-intensive field brazing, reducing installation complexity and minimizing the risk of human error.

How does insulation affect the performance of an air conditioning system?

Insulation in line sets prevents thermal loss and moisture absorption, thereby enhancing energy efficiency and protecting the system from potential damage.

Table of Contents

- Why 50ft is the Optimal Length for AC Line Sets

-

Labor & Cost Efficiency in Modern HVAC Installations

- Pre-Dehydrated Lines Accelerate Vacuum Process

- Standardized Lengths Simplify Contractor Inventory Management

- Reduced Field Measurements for Faster Deployment

- Avoiding Risky Couplings in Long Horizontal Runs

- Maintaining Proper Refrigerant Flow in Extended Systems

- Code Compliance for Maximum Linear Footage Between Units

- ASHRAE Guidelines for Copper Tubing Lengths

- Energy Star Recommendations for Insulated Line Sets

- Warranty Protection Through Approved Configurations

- Managing Excess Tubing in Compact Installations

- Preventing Oil Trapping in Extended Suction Lines

- UV-Resistant Jacketing for Outdoor Section Protection

- FAQ Section