Essential Guide to AC Connecting Pipes for Efficient Cooling

When it comes to maintaining an optimal cooling system in residential or commercial spaces, AC connecting pipes play a critical role. These pipes are the backbone of any air conditioning setup, facilitating the smooth flow of refrigerants and ensuring that the system operates efficiently. Selecting the right AC connecting pipes can directly influence cooling performance, energy consumption, and the overall longevity of your air conditioning system. Many users underestimate the importance of these pipes, but they are crucial components that bridge the gap between the indoor and outdoor units, allowing the system to deliver consistent cooling.

Understanding AC Connecting Pipes

Functionality of AC Connecting Pipes

AC connecting pipes are designed to transport refrigerants between the indoor and outdoor units. They are responsible for maintaining proper pressure levels and preventing leaks. Choosing high-quality AC connecting pipes ensures that your air conditioning system performs at its peak efficiency. The materials used in these pipes, typically copper or aluminum, also affect the system's durability. Copper pipes, for instance, offer excellent thermal conductivity and corrosion resistance, which translates to lower energy consumption and fewer maintenance requirements over time.

Importance in System Efficiency

The efficiency of an air conditioning system heavily depends on the performance of its connecting pipes. Poorly insulated or low-quality pipes can lead to energy losses, reducing cooling efficiency and increasing electricity bills. Properly installed AC connecting pipes help maintain the optimal temperature of refrigerants, minimizing wear and tear on compressors and other components. As a result, homeowners and businesses can enjoy reliable cooling performance while extending the life of their air conditioning units.

Materials and Design Considerations

Types of AC Connecting Pipes

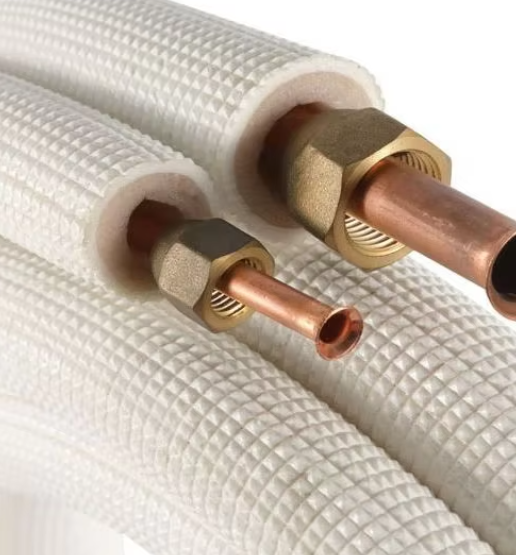

There are several types of AC connecting pipes available in the market, each designed to meet specific cooling requirements. Copper pipes are widely preferred due to their excellent thermal conductivity and resistance to corrosion. Aluminum pipes, on the other hand, are lightweight and cost-effective, making them suitable for certain applications. Flexible pipes are another option, allowing for easier installation in tight spaces and complex layouts. Understanding the differences between these materials and designs is essential when selecting the right pipes for your system.

Insulation and Durability

Insulation is a critical factor when it comes to AC connecting pipes. Well-insulated pipes prevent energy loss and protect refrigerants from temperature fluctuations. Insulation materials such as foam or rubber sleeves provide excellent protection against condensation, which can otherwise damage walls or ceilings. Durability is also key, as AC connecting pipes are exposed to various environmental conditions, including temperature variations, moisture, and physical stress. Choosing pipes with high-quality insulation ensures that your air conditioning system operates efficiently for years.

Installation Techniques

Professional Installation Practices

Proper installation of AC connecting pipes is vital to ensure optimal cooling performance. Professional technicians follow specific guidelines to avoid leaks, kinks, and improper bends that can compromise the system. Using specialized tools and fittings, installers ensure that pipes are securely connected and adequately insulated. This not only improves system efficiency but also reduces the risk of costly repairs in the future. Skilled installation practices also allow the system to maintain consistent refrigerant flow, which is essential for maintaining the desired indoor temperature.

Common Installation Challenges

While AC connecting pipes are relatively straightforward, several challenges can arise during installation. For example, routing pipes through walls or ceilings may require careful planning to avoid structural obstacles. Bending pipes incorrectly can lead to pressure loss and refrigerant leakage. Insufficient insulation can cause condensation issues, leading to water damage. Understanding these challenges helps in choosing the right installation approach, ensuring that your air conditioning system delivers efficient cooling without interruptions.

Maintenance Tips for Longevity

Regular Inspection and Cleaning

To keep AC connecting pipes in optimal condition, regular inspection is essential. Check for signs of wear, corrosion, or leaks, and clean any dust or debris that may accumulate around the pipes. Proper maintenance prevents blockages and ensures smooth refrigerant flow, enhancing the overall efficiency of your air conditioning system. Regular inspections also allow you to detect potential problems early, avoiding costly repairs and downtime.

Preventive Measures

Preventive maintenance measures can significantly extend the life of AC connecting pipes. Insulating pipes in areas exposed to extreme temperatures, avoiding sharp bends, and using protective coatings can reduce wear and tear. Additionally, monitoring the system’s performance helps identify irregularities that may indicate issues with the connecting pipes. Implementing preventive measures ensures that your air conditioning system continues to provide reliable and efficient cooling year-round.

Selecting the Right AC Connecting Pipes

Factors to Consider

When selecting AC connecting pipes, several factors must be considered. Material quality, diameter, length, and insulation type all influence the performance of the system. It is important to choose pipes that match the specifications of your air conditioning unit, as improper sizing can lead to reduced efficiency and increased energy consumption. Evaluating the durability and flexibility of the pipes also helps ensure long-term performance in diverse installation environments.

Cost and Value

While cost is an important consideration, it should not compromise quality. Investing in high-quality AC connecting pipes may have a higher upfront cost but can save money in the long term through reduced energy bills and fewer maintenance issues. Assessing the value of pipes based on material quality, durability, and insulation effectiveness allows users to make informed decisions that optimize system performance and reliability.

Energy Efficiency and Environmental Impact

Reducing Energy Consumption

Efficient AC connecting pipes contribute significantly to reducing energy consumption. By minimizing heat loss and maintaining optimal refrigerant flow, these pipes help the air conditioning system operate at peak performance. Lower energy consumption translates to reduced electricity bills and a smaller carbon footprint. High-quality pipes with proper insulation are an effective way to achieve sustainable cooling without compromising comfort.

Eco-Friendly Considerations

Choosing eco-friendly materials for AC connecting pipes, such as recyclable copper or aluminum, can also have a positive environmental impact. Additionally, efficient pipes reduce the overall energy demand of air conditioning systems, helping to conserve natural resources. By prioritizing environmentally responsible options, users can support sustainability while enjoying reliable and efficient cooling solutions.

Sino Material Technology — a Sino-US joint venture since 2014 — runs a 300,000 ft² plant with 7 lines, churning out ASTM/UL-certified PE, rubber and K-FLEX insulated copper pipes plus PVC covers for HVAC pros across the US, Europe and Australia.

One-stop shopping, short lead-times, top quality, happy customers: that’s our daily routine.

Need copper sets or covers fast? Ping Sino Material today and let’s get your order rolling!