Ghid esențial pentru conductele de conectare AC pentru o răcire eficientă

Atunci când este vorba de menținerea unui sistem de răcire optim în spații rezidențiale sau comerciale, Conductive de conexiune AC joacă un rol esențial. Aceste conducte sunt baza oricărui sistem de climatizare, facilitând curgerea lină a agenților frigorifici și asigurând funcționarea eficientă a sistemului. Alegerea corectă a conductelor de conectare AC poate influența direct performanța de răcire, consumul de energie și durata de viață generală a sistemului dvs. de climatizare. Mulți utilizatori subestimează importanța acestor conducte, dar acestea sunt componente cruciale care fac legătura între unitățile interioare și exterioare, permițând sistemului să ofere o răcire constantă.

Înțelegerea conductelor de conectare AC

Funcționalitatea conductelor de conectare AC

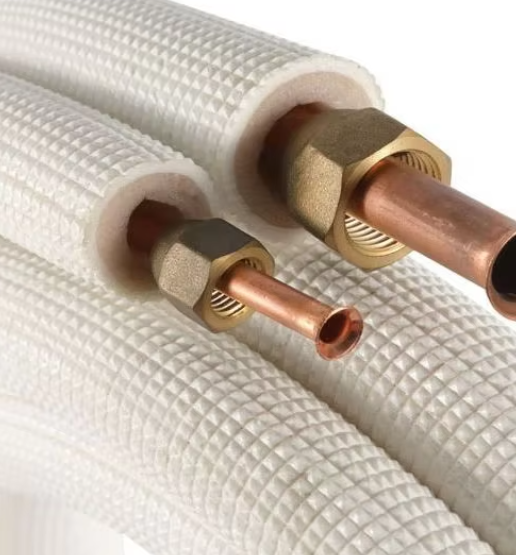

Conductele de conectare AC sunt proiectate pentru a transporta agenți frigorifici între unitățile interioare și exterioare. Ele sunt responsabile pentru menținerea unor niveluri adecvate de presiune și pentru prevenirea scurgerilor. Alegerea unor conducte de conectare AC de înaltă calitate asigură funcționarea sistemului de climatizare la eficiența maximă. Materialele utilizate în aceste conducte, în general cupru sau aluminiu, influențează și durabilitatea sistemului. Conductele din cupru, de exemplu, oferă o conductivitate termică excelentă și o rezistență ridicată la coroziune, ceea ce se traduce prin consum redus de energie și necesități mai mici de întreținere în timp.

Importanța pentru eficiența sistemului

Eficiența unui sistem de climatizare depinde în mare măsură de performanța conductelor de conectare. Conductele prost izolate sau de calitate scăzută pot duce la pierderi de energie, reducând eficiența răcirii și crescând facturile la electricitate. Conductele de conectare pentru aer condiționat instalate corect ajută la menținerea temperaturii optime a agenților frigorifici, minimizând uzura compresorului și a altor componente. Ca urmare, proprietarii de locuințe și afaceri pot beneficia de o performanță fiabilă de răcire, prelungind totodată durata de viață a unităților lor de climatizare.

Materiale şi consideraţii de proiectare

Tipuri de conducte de conectare pentru aer condiționat

Există mai multe tipuri de conducte de conectare AC disponibile pe piață, fiecare fiind proiectat pentru a satisface cerințele specifice de răcire. Conductele din cupru sunt larg preferate datorită conductivității termice excelente și rezistenței la coroziune. Conductele din aluminiu, pe de altă parte, sunt ușoare și rentabile, ceea ce le face potrivite pentru anumite aplicații. Conductele flexibile reprezintă o altă opțiune, permițând o instalare mai ușoară în spații limitate și configurații complexe. Înțelegerea diferențelor dintre aceste materiale și designuri este esențială atunci când se aleg conductele potrivite pentru sistemul dumneavoastră.

Izolație și durabilitate

Izolația este un factor esențial atunci când vine vorba de conductele de conectare ale aerului condiționat. Conductele bine izolate previn pierderea de energie și protejează agenții frigorifici de variațiile de temperatură. Materialele de izolație, cum ar fi manșoanele din spumă sau cauciuc, oferă o protecție excelentă împotriva condensului, care altfel ar putea deteriora pereții sau tavanul. Durabilitatea este, de asemenea, esențială, deoarece conductele de conectare ale aerului condiționat sunt expuse la diverse condiții mediului, inclusiv variații de temperatură, umiditate și stres fizic. Alegerea unor conducte cu o izolație de înaltă calitate asigură faptul că sistemul dumneavoastră de climatizare va funcționa eficient pe parcursul anilor.

Tehnici de instalare

Practici profesionale de instalare

Instalarea corectă a conductelor de conectare ale instalației de aer condiționat este esențială pentru asigurarea unei performanțe optime de răcire. Tehnicienii profesioniști urmează instrucțiuni specifice pentru a evita scurgerile, îndoirile și curbele incorecte care pot compromite sistemul. Utilizând unelte și accesorii specializate, instalatorii se asigură că conductele sunt conectate sigur și corespunzător izolate. Aceasta nu doar îmbunătățește eficiența sistemului, ci reduce și riscul unor reparații costisitoare în viitor. Practicile de instalare competente permit, de asemenea, sistemului să mențină un flux constant de agent frigorific, ceea ce este esențial pentru păstrarea temperaturii dorite în interior.

Provocări comune la instalare

Deși conductele de conectare ale aerului condiționat sunt relativ simple, pot apărea mai multe provocări în timpul instalării. De exemplu, traseul conductelor prin pereți sau tavan poate necesita o planificare atentă pentru a evita obstacolele structurale. Îndoirea incorectă a conductelor poate duce la pierderi de presiune și scurgeri de refrigerant. O izolație insuficientă poate provoca probleme de condens, ducând la deteriorarea cauzată de apă. Înțelegerea acestor provocări ajută la alegerea unei abordări corespunzătoare de instalare, asigurând că sistemul dumneavoastră de climatizare oferă o răcire eficientă fără întreruperi.

Sfaturi de întreținere pentru longevitate

Inspeție și curățenie regulată

Pentru a menține conductele de conectare ale aerului condiționat în stare optimă, este esențială o inspecție regulată. Verificați semnele de uzură, coroziune sau scurgeri și curățați orice praf sau resturi care s-ar putea acumula în jurul conductelor. O întreținere corespunzătoare previne blocările și asigură un flux lin al refrigerantului, îmbunătățind eficiența generală a sistemului de climatizare. Inspecțiile regulate vă permit, de asemenea, să detectați eventualele probleme din timp, evitând reparații costisitoare și opriri neprevăzute.

Măsuri preventive

Măsurile de întreținere preventivă pot prelungi în mod semnificativ durata de viață a conductelor de conectare ale aerului condiționat. Izolarea conductelor în zonele expuse la temperaturi extreme, evitarea coturilor ascuțite și utilizarea unor straturi protectoare pot reduce uzura. În plus, monitorizarea performanței sistemului ajută la identificarea anomaliilor care ar putea indica probleme legate de conductele de conectare. Aplicarea măsurilor preventive asigură faptul că sistemul dvs. de climatizare continuă să ofere o răcire fiabilă și eficientă pe tot parcursul anului.

Alegerea corectă a conductelor de conectare pentru aer condiționat

Factori de luat în considerare

La selectarea conductelor de conectare AC, trebuie luate în considerare mai multe factori. Calitatea materialului, diametrul, lungimea și tipul izolației influențează toți performanța sistemului. Este important să alegeți conducte care să corespundă specificațiilor unității de climatizare, deoarece o dimensionare necorespunzătoare poate duce la o eficiență redusă și la o creștere a consumului de energie. Evaluarea durabilității și flexibilității conductelor ajută, de asemenea, la asigurarea unei performanțe pe termen lung în diverse medii de instalare.

Cost și valoare

Deși costul este o considerație importantă, acesta nu ar trebui să compromită calitatea. Investiția în conducte de înaltă calitate pentru conectarea AC poate implica un cost inițial mai mare, dar poate economisi bani pe termen lung prin reducerea facturilor la energie și a problemelor de întreținere. Evaluarea valorii conductelor în funcție de calitatea materialului, durabilitate și eficacitatea izolației permite utilizatorilor să ia decizii informate care optimizează performanța și fiabilitatea sistemului.

Eficiența energetică și impactul asupra mediului

Reducerea Consumului de Energie

Conductele eficiente de conectare AC contribuie semnificativ la reducerea consumului de energie. Prin minimizarea pierderilor de căldură și menținerea unui flux optim al agentului frigorific, aceste conducte ajută sistemul de climatizare să funcționeze la performanță maximă. Un consum mai scăzut de energie se traduce prin facturi mai mici la electricitate și o amprentă de carbon redusă. Conductele de înaltă calitate, cu izolație corespunzătoare, reprezintă o modalitate eficientă de a obține o răcire durabilă fără a compromite confortul.

Considerente Ecoresponsabile

Alegerea materialelor ecologice pentru conductele de conectare AC, cum ar fi cuprul sau aluminiul reciclabil, poate avea de asemenea un impact pozitiv asupra mediului. În plus, conductele eficiente reduc cererea generală de energie a sistemelor de climatizare, contribuind astfel la conservarea resurselor naturale. Prioritizând opțiuni responsabile din punct de vedere ambiental, utilizatorii pot sprijini sustenabilitatea, beneficiind totodată de soluții de răcire fiabile și eficiente.

Sino Material Technology — o joint venture sino-americană din 2014 — deține o uzină de 300.000 ft² cu 7 linii, producând țevi din cupru izolate cu PE, cauciuc și K-FLEX, certificate ASTM/UL, precum și învelișuri din PVC pentru specialiștii HVAC din SUA, Europa și Australia.

Cumpărături la un loc, termene scurte de livrare, calitate superioară, clienți mulțumiți: aceasta este rutina noastră zilnică.

Aveți nevoie rapid de seturi din cupru sau învelișuri? Contactați azi Sino Material și să pornim comanda dvs.!