What Makes PVC Line Set Covers Essential for HVAC Systems

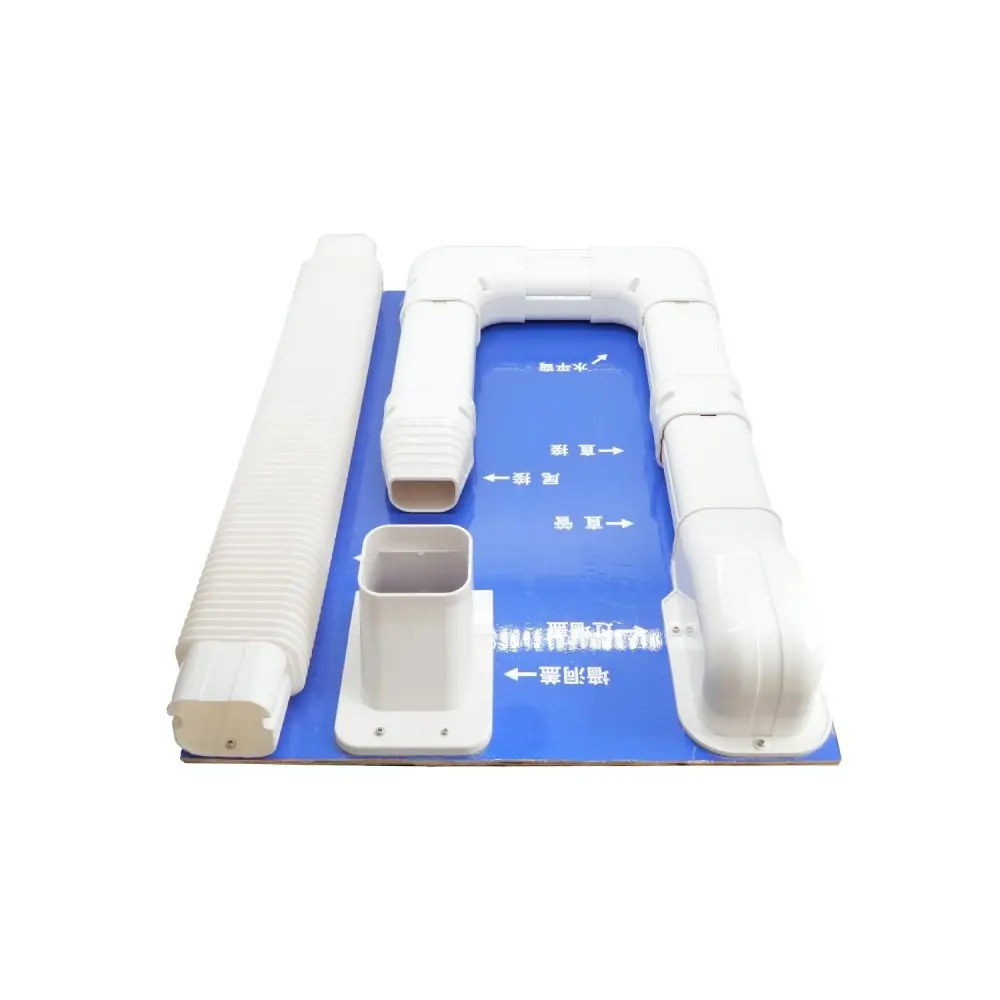

Components of a PVC Line Set Cover System

PVC line set cover systems really help boost HVAC efficiency because they include some essential parts. Most installations have the actual covers plus adhesives and strong fasteners to keep everything secure. Together, these pieces protect refrigerant lines and electrical wires from damage caused by weather, debris, or accidental impacts during maintenance work. According to field tests conducted across multiple climate zones, properly installed line set covers can cut down on energy waste by around 20%. The right fit matters a lot too since gaps or loose fittings let heat escape, which wears out the whole system faster over time. Installers who take care with these details often see longer lasting equipment with fewer breakdowns in the long run.

Protection Against Environmental Damage

PVC line set covers really do protect HVAC systems from those tough outdoor conditions nobody wants to deal with. They keep the lines safe from sun damage, hail storms, and all sorts of temperature extremes that would otherwise wreck havoc on the equipment and rack up expensive repair bills. According to what we see in the field, systems exposed to weather without proper covering tend to cost around 30% more in fixes compared to protected ones. The fact that PVC is so tough means these systems last longer too. Over time, they just handle whatever Mother Nature throws at them without needing constant checking or fixing.

Durability Advantages of PVC Line Set Covers

UV-Resistant PVC for Long-Term Reliability

The UV resistance of PVC line set covers makes them stand out when it comes to lasting reliability. Most other materials just don't hold up under constant sun exposure, but PVC comes with natural protection against UV damage right from the start. This matters a lot since UV radiation breaks down many materials over time, causing everything from decreased efficiency to outright system failure. Field data shows that without proper UV protection, HVAC line sets can lose about half their expected lifespan simply due to sun damage. Technicians working in places like Arizona or Florida regularly point out how well PVC performs even during those brutal summer months. By choosing PVC with good UV resistance, facility managers keep their HVAC systems running smoothly year after year while cutting down on both repair calls and replacement expenses.

Impact on HVAC System Longevity

Protective PVC line set covers really do make a difference when it comes to how long HVAC systems last. These covers protect the sensitive parts from all sorts of environmental problems, which means less need for constant fixing and maintenance work. Studies comparing different setups show that systems with PVC covers tend to run smoother with fewer breakdowns and lower repair bills overall. Take systems that don't have this protection - they usually end up costing more because things break down faster from weather damage or accidental knocks. The tough nature of PVC materials keeps the system intact and working properly. For building managers looking at their bottom line, installing these covers makes sense as part of regular maintenance routines. They keep the system running better for longer periods, cut down on those unexpected repair expenses, and generally make the whole operation more reliable day after day.

Aesthetic Benefits of Using PVC Line Set Solutions

Blending with Architectural Designs

PVC line set covers come in all sorts of colors and styles that just blend right in with different building designs. They really work well for homes as well as businesses wanting to keep things looking good together. When it comes to commercial properties, how something looks matters a lot because people form opinions based on appearances. Take shopping centers for instance, nobody wants to see ugly pipes sticking out everywhere. Getting the right color cover makes those boring installation spots look nice instead. Some builders even go out of their way to match existing color schemes so everything flows better visually across the whole property.

Paintable Surfaces for Customization

PVC line set covers come with a major plus point their surfaces can be painted, letting homeowners customize them however they want. When folks take the time to prep the surface right before adding paint, they end up creating really cool designs that make their space look better overall. People generally feel happier in places where they've added personal touches, forming stronger connections with their surroundings whether at home or work. These customizable PVC options offer protection for HVAC systems while still allowing folks to match colors and styles that fit their personality and complement existing architecture. Some even go as far as matching wall colors or incorporating decorative patterns that reflect individual taste.

PVC Line Set Covers and HVAC Performance

Thermal Efficiency Improvements

PVC line set covers make a big difference in how well HVAC systems handle temperature control. Research shows these covers keep refrigerant lines at their best operating temps, which actually makes the whole system work better. The insulation stops unwanted heat transfer so the system doesn't have to work as hard to adjust temperatures, cutting down on energy bills. Some tests indicate buildings using these covers see around a 15% drop in energy usage. For property managers looking to cut costs while being eco-friendly, installing line set covers is a smart move that works equally well for homes and office buildings alike.

Preventing Refrigerant Line Insulation Degradation

Keeping refrigerant lines protected against insulation breakdown matters a lot for good HVAC system performance, and PVC covers are pretty important in this whole equation. They act as barriers against all sorts of environmental stuff like sun exposure, moisture from rainwater, and accidental bumps or knocks that gradually wear things down over time. When insulation starts to fail, we often see refrigerant leaks happen along with reduced system efficiency, which means higher bills and costly fixes down the road. Putting on those PVC coverings actually makes a big difference in how long the insulation lasts and keeps working properly, so damage doesn't occur as easily. Maintenance crews should check these covers at least once every six months looking for any signs of cracking or peeling, and make sure they're installed correctly according to manufacturer guidelines to get maximum protection value out of them.

Installation Considerations for PVC Line Sets

Step-by-Step Installation Process

Getting PVC line set covers installed correctly makes a big difference in how well HVAC systems perform and last over time. Start by picking out a cover that fits the size and shape of those refrigerant lines running around. Before starting work, make sure everything needed is on hand including mounting hardware, brackets, and all necessary fasteners. When placing the cover over the lines, secure it properly using brackets spaced evenly along the length for good support. The modular sections might need some adjustment depending on exactly how the system is laid out in different spaces. Always double check where things line up because even small gaps can let moisture get in and cause problems down the road. Most folks would do better getting someone experienced to handle this job, but there are plenty of detailed tutorials online for those who want to tackle it themselves. Just remember that precision matters a lot here, especially when dealing with complex installations.

Mitsubishi Line-Hide Compatibility Insights

Most PVC line set covers work pretty well with Mitsubishi HVAC systems and offer several advantages during installation, particularly when hiding lines is needed. They fit nicely into Mitsubishi configurations while protecting the lines from weather damage and accidental bumps or scratches. When installers choose the right PVC covers for their Mitsubishi equipment, they're basically wrapping up those refrigerant lines in a protective layer that keeps things running smoothly over time. According to field technicians who have worked on hundreds of these systems, properly matched PVC line set covers actually help improve how efficiently heat moves through the system and tend to make the whole unit last longer. That's why smart contractors always take extra care picking out coverings that match their Mitsubishi gear specifications exactly.

Comparing PVC to Alternative Line Set Materials

PVC vs Rubber Line Set Covers

Deciding between PVC and rubber line set covers involves looking at a few different aspects. PVC stands out because it lasts longer, since it can handle impacts pretty well, doesn't break down when exposed to chemicals, and holds up against weather conditions too. This means HVAC systems stay protected for years without needing replacement. Rubber options do have their benefits though - they bend easily which makes them good for certain applications. But rubber just doesn't stand up as well against harsh environments compared to PVC. Most people find that PVC actually saves money in the long run despite higher initial costs. Industry pros generally recommend going with PVC when strength and looks matter most. Still worth considering rubber if flexibility matters more than anything else, especially when working within tight budgets or dealing with complex installation requirements.

Cost-Effectiveness vs Copper Shielding

When looking at what works best for the wallet, PVC line set covers really beat out copper shielding while still giving good protection. Copper does have that great heat transfer property which helps keep refrigerant temps stable, but let's face it the price tag for buying and installing copper just doesn't fit most project budgets. Most installers will tell you PVC is way cheaper to work with, saving money upfront during installation and again later when maintenance comes around. For jobs where budget matters most and keeping things protected from elements is important, PVC makes sense. But for those special cases where every degree of temperature control counts, some folks still go with copper despite the higher costs.

Sustainability of PVC Line Set Solutions

Recyclability and Environmental Impact

PVC stands out when it comes to being able to recycle and having a smaller environmental impact than many other materials on the market today. Line set covers made from PVC materials usually end up getting recycled rather than going straight into landfills, which cuts down on all that extra waste created by HVAC installations. Looking at how long these products last in real world conditions shows why PVC remains a sustainable option. These things don't need replacing as often as alternatives do because they just hold up better under normal wear and tear. Take for example the way PVC resists degradation over years of service, meaning fewer discarded components piling up in garbage dumps. Most contractors know this already since they see firsthand how PVC performs in actual installation scenarios. Beyond just keeping trash levels down, choosing PVC for line sets actually aligns with broader green building objectives while still delivering reliable performance. That's probably why so many construction professionals continue to favor PVC despite whatever marketing claims competitors might make about their own products.

Energy Savings Through Improved Insulation

PVC line set covers actually save quite a bit of energy because they provide better insulation than standard materials. These covers keep HVAC systems running efficiently since they cut down on heat loss, meaning less energy gets wasted and monthly bills go down over time. According to industry reports, buildings with properly installed PVC insulated line sets typically see around 15% reduction in their energy expenses while also cutting carbon footprints significantly. Looking ahead, many professionals think we'll continue seeing improvements in PVC insulation technology as building owners become more concerned about energy efficiency. This growing interest suggests that PVC will play an important part in shaping how we build energy efficient structures going forward.

Frequently Asked Questions

What are the primary benefits of using PVC line set covers?

PVC line set covers enhance HVAC system efficiency by protecting refrigerant lines and electrical wiring from environmental damage. They provide crucial UV resistance, improve thermal insulation, and offer customizable aesthetic options.

How do PVC covers contribute to HVAC system longevity?

The durability and protection offered by PVC covers minimize maintenance needs, reduce failure rates, and prolong the lifespan of HVAC systems. They shield components from environmental stress, which can otherwise lead to costly repairs.

Can PVC line set covers be customized?

Yes, PVC line set covers can be painted to match architectural designs, offering complete customization to fit unique aesthetic preferences while maintaining their protective qualities.

Why choose PVC over other materials like rubber or copper?

PVC offers cost-effective, long-lasting protection with recyclability benefits without compromising performance. It is more durable than rubber and provides ample protection compared to copper at a lower price point.

Table of Contents

- What Makes PVC Line Set Covers Essential for HVAC Systems

- Durability Advantages of PVC Line Set Covers

- Aesthetic Benefits of Using PVC Line Set Solutions

- PVC Line Set Covers and HVAC Performance

- Installation Considerations for PVC Line Sets

- Comparing PVC to Alternative Line Set Materials

- Sustainability of PVC Line Set Solutions

- Frequently Asked Questions