چه چیزی پوششهای مجموعه لوله PVC را برای سیستمهای HVAC ضروری میکند

프로그tréنهای یک جعبه جوشکاری پی وی سی سیستم

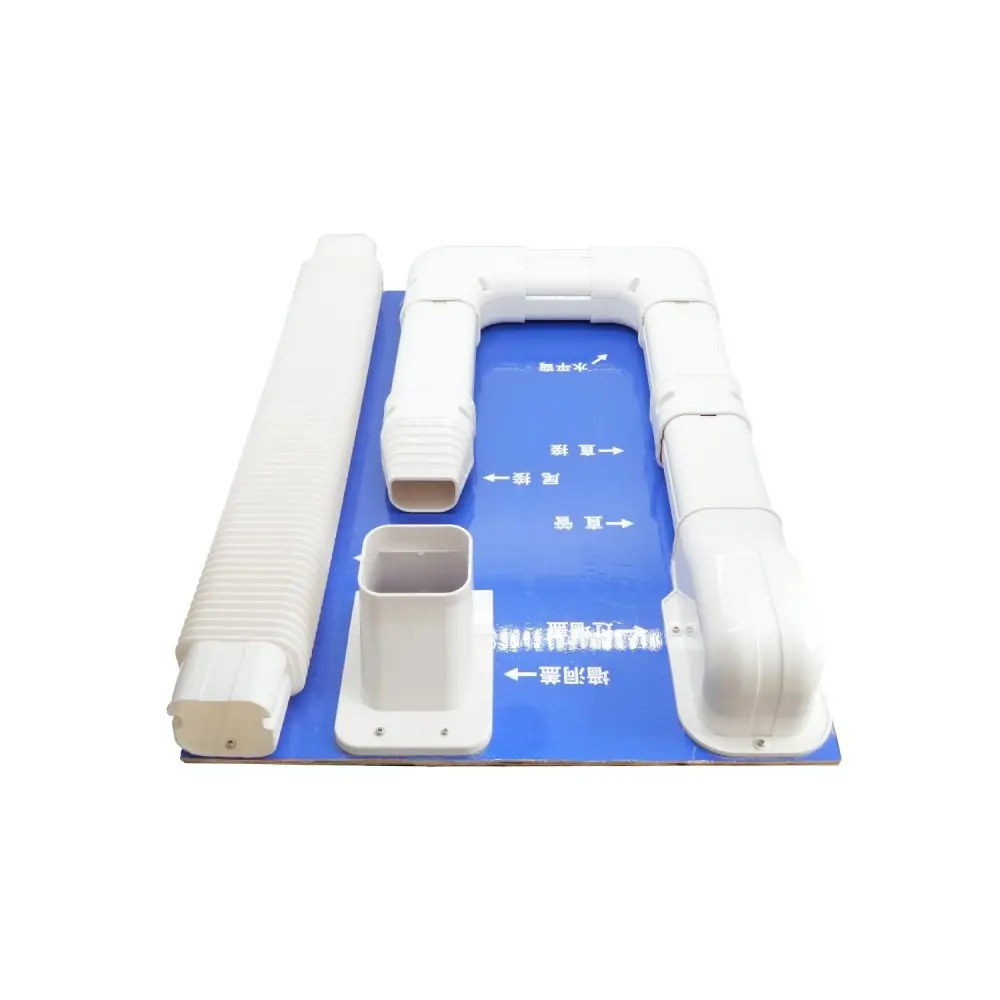

سیستمهای پوشش لولهکشی PVC واقعاً به افزایش کارایی سیستمهای اچویاک (HVAC) کمک میکنند، چون شامل برخی قطعات ضروری هستند. بیشتر نصبها شامل پوششهای واقعی به همراه چسبها و فیکسچرها (نگهدارندههای محکم) برای نگه داشتن همه چیز در جای خود است. این قطعات با هم خطوط مبرد و سیمهای برقی را از آسیبهای ناشی از شرایط جوی، آشغالها یا ضربههای تصادفی در حین تعمیرات محافظت میکنند. بر اساس آزمایشهای میدانی که در مناطق مختلف اقلیمی انجام شده، پوششهای لولهکشی نصب شده به درستی میتوانند اتلاف انرژی را تا حدود 20 درصد کاهش دهند. هماهنگی مناسب هم خیلی مهم است، چون شکافها یا اتصالات شل اجازه میدهند گرما فرار کند و این موضوع باعث میشود سیستم کلی زودتر از کار بیفتد. نصابانی که به این جزئیات توجه میکنند، اغلب تجهیزاتی با دوامتر و با شکستهای کمتر در طول زمان را تجربه میکنند.

محافظت در برابر خسارات محیطی

پوششهای لاین ست PVC واقعاً سیستمهای HVAC را در برابر شرایط سخت آب و هوایی که هیچکس دوست ندارد با آن سر و کار داشته باشد، محافظت میکنند. این پوششها خطوط را در برابر آسیبهای ناشی از تابش خورشید، باران سنگین، و انواع شرایط دمایی بسیار قرار گرفته در دماهای بسیار بالا یا پایین که میتوانند خسارت زیادی به تجهیزات وارد کنند و صورتهای هزینهبر برق بیاورند، ایمن نگه میدارند. بر اساس مشاهدات ما از زمینه کار، سیستمهایی که بدون پوشش مناسب در معرض عوامل جوی قرار میگیرند، حدوداً ۳۰ درصد هزینه تعمیرات بیشتری نسبت به سیستمهای محافظت شده دارند. مقاومت بالایی که PVC دارد به این معنی است که این سیستمها دوام بیشتری هم دارند. در طول زمان، آنها بدون نیاز به بازرسی یا تعمیرات مکرر، هر آنچه را که طبیعت به سمت آنها میاندازد به خوبی پشت سر میگذارند.

مزایای دوام بالای پوششهای لاینسیت PVC

PVC مقاوم در برابر اشعه ماوراء بنفش برای قابلیت اطمینان بلندمدت

مقاومت در برابر UV در پوششهای لاینست PVC باعث میشود تا این محصول از لحاظ دوام و قابلیت اطمینان طولانیمدت متمایز شود. بیشتر مواد دیگر در معرض تابش مداوم خورشید دوام لازم را ندارند، اما PVC از همان ابتدا دارای حفاظت طبیعی در برابر آسیبهای ناشی از UV است. این موضوع اهمیت زیادی دارد، چرا که تابش فرابنفش باعث تخریب بسیاری از مواد با گذشت زمان میشود و میتواند منجر به کاهش بهرهوری و حتی خرابی کامل سیستم شود. دادههای میدانی نشان میدهند که در صورت عدم وجود حفاظت مناسب در برابر UV، لاینستهای HVAC ممکن است تا نصف عمر مورد انتظار خود را به دلیل آسیبهای ناشی از تابش خورشید از دست بدهند. تکنسینهایی که در مناطقی مانند آریزونا یا فلوریدا کار میکنند، به طور منظم به عملکرد خوب PVC حتی در طول ماههای سخت تابستان اشاره میکنند. با انتخاب PVC با مقاومت خوب در برابر UV، مدیران تاسیسات میتوانند سیستمهای HVAC خود را به طور مداوم و بدون مشکل از سالی به سال دیگر نگه دارند و همچنین هزینههای تعمیر و تعویض را کاهش دهند.

تأثیر روی دوام سیستم HVAC

پوششهای پیویسی برای لاینست واقعاً تفاوت ایجاد میکنند که چقدر سیستمهای اچویاک (HVAC) دوام میآورند. این پوششها قسمتهای حساس را از انواع مشکلات محیطی محافظت میکنند و در نتیجه نیاز به تعمیرات و نگهداری مداوم کمتری پیش میآید. مطالعات مقایسهکننده سیستمهای مختلف نشان دادهاند که سیستمهایی که از پوششهای پیویسی استفاده میکنند، بهطور کلی روانتر کار میکنند، دچار مشکلات کمتری میشوند و در مجموع هزینههای تعمیراتی کمتری دارند. حالا سیستمهایی را در نظر بگیرید که از این پوششها استفاده نمیکنند؛ این سیستمها تمایل دارند هزینههای بیشتری داشته باشند، چون خرابیها بهسرعت از بابت آسیبهای ناشی از شرایط جوی یا ضربههای اتفاقی رخ میدهد. ماهیت مقاوم مصالح پیویسی باعث میشود سیستم بدون آسیب باقی بماند و بهدرستی کار کند. برای مدیران ساختمان که به دنبال صرفهجویی در هزینههای عملیاتی هستند، نصب این پوششها بهعنوان بخشی از روالهای معمول نگهداری منطقی است. این پوششها به عملکرد بهتر و طولانیتر سیستم کمک میکنند، هزینههای غیرمنتظره تعمیرات را کاهش میدهند و در مجموع باعث میشوند که عملیات روزانه قابلاطمینانتر شود.

مزایای زیبایی حاصل از استفاده از راهکارهای لاین ست PVC

هماهنگی با طراحیهای معماری

پوششهای لولهکشی PVC در انواع رنگها و طرحهای مختلفی موجود هستند که به راحتی با طراحیهای ساختمانی گوناگون هماهنگ میشوند. این پوششها به خوبی برای منازل و همچنین اماکن کسبی که میخواهند ظاهری یکدست و زیبا داشته باشند، کاربرد دارند. در مورد ساختمانهای تجاری، ظاهر بسیار اهمیت دارد، چون مردم اغلب نظرات خود را بر اساس همین دیداری شکل میدهند. برای مثال در مراکز خرید، هیچکس نمیخواهد لولههای زشت و برجستهای در همه جا دیده شود. انتخاب پوشش رنگی مناسب میتواند این نقاط نصب کسلکننده را تبدیل به یک ظاهر خوب کند. برخی از سازندگان حتی تلاش میکنند رنگهای موجود را با طرح کلی ساختمان هماهنگ کنند تا انسجام بصری بهتری در کل ملک ایجاد شود.

سطحهای قابل رنگآمیزی برای شخصیسازی

پوششهای لولهکشی PVC دارای یک مزیت بزرگ هستند و آن اینکه سطح آنها را میتوان رنگ کرد و این امکان را به مالکان خانه بدهد تا آنها را به هر شکلی که میخواهند شخصیسازی کنند. وقتی افراد قبل از رنگآمیزی به درستی سطح را آماده میکنند، طرحهای فوقالعاده زیبایی ایجاد میکنند که ظاهر کلی فضای آنها را بهتر میکند. افراد عموماً در فضاهایی که دستکاری شخصی در آنها شده است احساس خوشایندی بیشتری دارند و پیوند قویتری با محیط اطراف خود در خانه یا محل کار برقرار میکنند. این گزینههای PVC قابل شخصیسازی، حفاظت از سیستمهای اچ ویسی (HVAC) را فراهم میکنند و در عین حال این امکان را به افراد میدهند تا رنگها و سبکها را با شخصیت و معماری موجود تطبیق دهند. برخی از افراد حتی تا حد تطبیق رنگ دیوار یا استفاده از الگوهای تزیینی که سلیقه فردی آنها را منعکس میکنند پیش میروند.

پوششهای لولهکشی PVC و عملکرد HVAC

بهبود بازده حرارتی

پوششهای لولهکشی PVC تفاوت بزرگی در نحوه کنترل دما توسط سیستمهای HVAC ایجاد میکنند. مطالعات نشان میدهند که این پوششها دمای بهینه خطوط مبرد را حفظ میکنند، به گونهای که در واقع کارایی کل سیستم را بهبود میبخشند. عایقبندی انتقال گرما به صورت ناخواسته را متوقف میکند، به طوری که سیستم مجبور نیست برای تنظیم دما تلاش بیشتری کند و این امر منجر به کاهش هزینههای انرژی میشود. برخی آزمایشها نشان میدهند که ساختمانهایی که از این پوششها استفاده میکنند حدوداً 15 درصد مصرف انرژی خود را کاهش میدهند. برای مدیران املاکی که به دنبال کاهش هزینهها با رعایت سبک زندگی سازگار با محیط زیست هستند، نصب پوششهای لولهکشی اقدام هوشمندانهای است که به یک اندازه برای خانهها و ساختمانهای اداری کارایی دارد.

جلوگیری از تخریب عایق لولههای مبرد

حفاظت از خطوط مبرد در برابر شکست عایقی برای عملکرد مناسب سیستم HVAC اهمیت زیادی دارد و پوششهای PVC در این معادله نقش مهمی ایفا میکنند. آنها به عنوان سدی در برابر عوامل مختلف محیطی مانند تابش خورشید، رطوبت ناشی از باران و ضربههای تصادفی عمل میکنند که به مرور زمان باعث فرسودگی میشوند. زمانی که عایق دچار شکست میشود، اغلب نشتی مبرد و کاهش کارایی سیستم را شاهد هستیم، که این امر به معنای صورتهای بیشتر و تعمیرات پرهزینه در آینده است. استفاده از این پوششهای PVC در واقع تفاوت زیادی در مدت زمانی که عایق دوام میآورد و به خوبی کار میکند ایجاد میکند، بنابراین آسیبها به راحتی رخ نمیدهد. تیمهای نگهداری باید هر شش ماه یکبار این پوششها را از نظر ترکهای احتمالی یا بلند شدگی بررسی کنند و مطمئن شوند که نصب آنها دقیقاً مطابق دستورالعملهای تولیدکننده انجام شده است تا حداکثر مقدار حفاظت را فراهم کنند.

نکات نصب مجموعه خطوط PVC

فرآیند نصب گام به گام

نصب صحیح پوششهای خط لوله PVC تفاوت بزرگی در عملکرد و دوام سیستمهای HVAC ایجاد میکند. ابتدا یک پوشش را انتخاب کنید که با اندازه و شکل خطوط سرمازا که در سراسر سیستم قرار دارند، مطابقت داشته باشد. قبل از شروع کار، مطمئن شوید تمامی موارد لازم اعم از لوازم نگهدارنده، پایهها و پیچهای مورد نیاز در دسترس باشند. هنگام قرار دادن پوشش روی لولهها، آن را با پایههایی که بهصورت یکنواخت در طول لوله قرار گرفتهاند، بهخوبی محکم کنید. بخشهای ماژولار ممکن است نیاز به تنظیم داشته باشند بسته به نحوه قرارگیری سیستم در فضاهای مختلف. همیشه دقت کنید که قطعات بهخوبی در یک راستا قرار گرفته باشند، چون حتی شکافهای کوچک نیز میتوانند باعث نفوذ رطوبت و ایجاد مشکلات در آینده شوند. بیشتر افراد بهتر است این کار را به یک فرد با تجربه بسپارند، اما برای کسانی که میخواهند خودشان این کار را انجام دهند، آموزشهای مفصلی در دسترس هستند. فقط به یاد داشته باشید که دقت در این کار بسیار مهم است، بهویژه در موارد نصبهای پیچیده.

اطلاعات سازگاری Mitsubishi Line-Hide

پوششهای لولهکشی PVC در بیشتر موارد به خوبی با سیستمهای HVAC میتسوبیشی کار میکنند و در زمان نصب مزایای متعددی ارائه میدهند، به خصوص هنگامی که نیاز است لولهها پنهان شوند. این پوششها به خوبی در کانفیگهای میتسوبیشی جا میشوند و از لولهها در برابر آسیبهای ناشی از شرایط جوی و ضربههای تصادفی یا خطهای ایجاد شده محافظت میکنند. وقتی نصابان پوششهای مناسب PVC را برای تجهیزات میتسوبیشی خود انتخاب میکنند، در واقع لولههای مبرد را با یک لایه محافظ احاطه میکنند که باعث میشود سیستم به طور طولانیمدت به خوبی کار کند. بر اساس گفته تکنسینهای مجربی که روی صدها دستگاه این چنینی کار کردهاند، پوششهای مناسب لولهها باعث بهبود کارایی انتقال گرما در سیستم شده و عمر کلی واحد را افزایش میدهند. به همین دلیل است که پیمانکاران باهوش همیشه وقت میگذارند تا پوششهایی را انتخاب کنند که دقیقاً با مشخصات تجهیزات میتسوبیشی آنها هماهنگ باشد.

مقایسه PVC با دیگر مواد لولهکشی

PVC در مقابل پوششهای لاستیکی لولهکشی

تصمیمگیری بین پوششهای لولهکشی از جنس PVC و لاستیکی شامل بررسی چندین جنبه مختلف است. PVC به دلیل دوام بیشتر برجسته میشود، زیرا میتواند ضربهها را به خوبی تحمل کند، در برابر مواد شیمیایی مقاوم است و همچنین در برابر شرایط جوی مقاومت میکند. این موضوع به این معنی است که سیستمهای HVAC سالها حفاظت میشوند و نیازی به تعویض ندارند. گزینههای لاستیکی هم مزایای خودشان را دارند - انعطافپذیری بالایی دارند و بنابراین برای برخی کاربردها مناسب هستند. اما لاستیک در محیطهای سخت نمیتواند عملکرد خوبی نسبت به PVC داشته باشد. بیشتر افراد در مییابند که PVC در بلندمدت صرفهجویی در هزینه دارد، هرچند در ابتدا هزینه بیشتری داشته باشد. متخصصان صنعت عموماً PVC را زمانی پیشنهاد میکنند که استحکام و ظاهر اهمیت بیشتری داشته باشد. با این حال، اگر انعطافپذیری از هر چیز دیگری اهمیت بیشتری داشته باشد، به خصوص در شرایطی که بودجه محدود است یا نصب پیچیده است، استفاده از لاستیک همچنان قابل توجه است.

مقرونبهصرفهبودن vs حفاظت مسی

هنگام بررسی اینکه چه چیزی از نظر هزینه به صرفهتر است، پوششهای خط لوله PVC واقعاً عملکرد بهتری نسبت به محافظت از جنس مس ارائه میدهند، در حالی که حفاظت خوبی نیز فراهم میکنند. مس البته خاصیت انتقال حرارت بسیار خوبی دارد که به ثابت نگه داشتن دمای مبرد کمک میکند، اما باید بپذیریم که هزینه خرید و نصب مس با بودجه بیشتری از پروژههای اکثر ما همخوانی ندارد. بیشتر نصابان میگویند که کار با PVC بسیار ارزانتر است و هم در زمان نصب و هم در زمان تعمیرات و نگهداری بعدی، هزینه را کاهش میدهد. برای پروژههایی که بودجه اصلی اولویت است و حفاظت از عناصر مهم است، استفاده از PVC منطقی است. اما در موارد خاصی که کنترل دما در هر درجه اهمیت دارد، برخی افراد با وجود هزینههای بالاتر همچنان به مس روی میآورند.

پایداری راهکارهای مجموعه خط لوله PVC

بازیافت و تاثیرات زیست محیطی

در زمینه قابلیت بازیافت و داشتن تأثیر محیطزیستی کمتر از بسیاری از سایر مواد موجود در بازار، PVC از خود برجستگی نشان میدهد. پوششهای مجموعه لولهکشی که از مواد PVC ساخته میشوند، معمولاً بازیافت میگردند و به جای پر کردن محلهای دفن زباله، این موضوع باعث کاهش زبالههای اضافی ایجاد شده توسط نصب سیستمهای تهویه مطبوع میشود. مدت زمان طولانی عمر این محصولات در شرایط واقعی نشان میدهد که چرا PVC همچنان گزینهای پایدار محسوب میشود. این محصولات به دلیل مقاومت بیشتر در برابر فرسایش ناشی از استفاده عادی، نیاز به تعویض مکرر کمتری دارند. به عنوان مثال، PVC در طول سالها مقاومت خود را حفظ میکند و این موضوع باعث میشود تعداد کمتری از قطعات قدیمی در محلهای دفن زباله انباشته شوند. بیشتر پیمانکاران این موضوع را میدانند، چرا که آنها به طور مستقیم عملکرد PVC را در شرایط واقعی نصب مشاهده کردهاند. انتخاب PVC برای مجموعه لولهکشی تنها کاهش سطح زبالهها را به همراه نمیآورد، بلکه در واقع با اهداف گستردهتر ساختمانهای سبز نیز همراستا است و در عین حال عملکرد قابل اطمینانی را فراهم میکند. این احتمالاً دلیل این است که چرا بسیاری از متخصصان ساختمانی امروزه همچنان PVC را ترجیح میدهند، هرچند که رقبا ممکن است ادعاهای تبلیغاتی در مورد محصولات خود داشته باشند.

صرفهجویی در انرژی از طریق عایولبندی بهتر

پوششهای خط لوله از جنس PVC در واقع مقدار قابل توجهی انرژی را ذخیره میکنند، زیرا عایق بهتری نسبت به مواد استاندارد فراهم میکنند. این پوششها باعث میشوند سیستمهای گرمایشی و سرمایشی بهصورت کارآمدتری کار کنند، زیرا از اتلاف گرما کم میکنند و در نتیجه انرژی کمتری هدر میرود و قبوض ماهانه با گذشت زمان کاهش مییابد. بر اساس گزارشهای صنعتی، ساختمانهایی که مجموعه خطوط لوله آنها بهدرستی با عایق PVC نصب شده است، معمولاً حدود 15٪ کاهش در هزینههای انرژی را تجربه میکنند، در حالی که اثر کربنی خود را نیز بهطور قابل توجهی کاهش دادهاند. با نگاهی به آینده، بسیاری از متخصصان فکر میکنند که بهبودهای مداوم در فناوری عایقبندی PVC را خواهیم دید، زیرا مالکان ساختمانها به سوی نگرانی بیشتر درباره کارایی انرژییکی حرکت میکنند. این علاقه روبهرشد نشان میدهد که PVC نقش مهمی در شکلدهی به نحوه ساخت ساختمانهای کارآمد از نظر مصرف انرژی در آینده خواهد داشت.

سوالات متداول

مزایای اصلی استفاده از پوششهای لولهکشی PVC چیست؟

پوششهای لولهکشی PVC با حفاظت از خطوط مبرد و سیمکشی برق در مقابل آسیبهای محیطی، کارایی سیستمهای HVAC را افزایش میدهند. این پوششها مقاومت فرابنفش ضروری فراهم میکنند، عایلبندی حرارتی را بهبود میبخشند و گزینههای زیبایی قابل تنظیمی ارائه میدهند.

پوششهای PVC چگونه به افزایش عمر سیستمهای HVAC کمک میکنند؟

دوام و حفاظتی که پوششهای PVC ارائه میدهند، نیاز به نگهداری را کاهش داده، نرخ خرابی را پایین میآورد و عمر مفید سیستمهای HVAC را افزایش میدهد. این پوششها از قطعات در برابر تنشهای محیطی محافظت میکنند که در غیر این صورت میتوانست منجر به تعمیرات پرهزینه شود.

آیا پوششهای لولهکشی PVC قابل سفارشیسازی هستند؟

بله، پوششهای لولهکشی PVC را میتوان به رنگهای مختلفی رنگ کرد تا با طرحهای معماری هماهنگ شوند و کاملترین سفارشیسازی را برای تطبیق با سلیقههای زیبایی خاص فراهم کنند، در حالی که خواص محافظتی خود را حفظ میکنند.

چرا باید از PVC به جای سایر مواد مانند لاستیک یا مس استفاده کرد؟

PVC ارائهدهنده حفاظت مقرونبهصرفه و با دوام است که مزایای قابلیت بازیافت را بدون compromise در عملکرد فراهم میکند. این ماده نسبت به لاستیک مقاومتر است و در مقایسه با مس، حفاظت بیشتری را در قیمت پایینتری ارائه میدهد.

فهرست مطالب

- چه چیزی پوششهای مجموعه لوله PVC را برای سیستمهای HVAC ضروری میکند

- مزایای دوام بالای پوششهای لاینسیت PVC

- مزایای زیبایی حاصل از استفاده از راهکارهای لاین ست PVC

- پوششهای لولهکشی PVC و عملکرد HVAC

- نکات نصب مجموعه خطوط PVC

- مقایسه PVC با دیگر مواد لولهکشی

- پایداری راهکارهای مجموعه خط لوله PVC

- سوالات متداول